Empowering Excellence

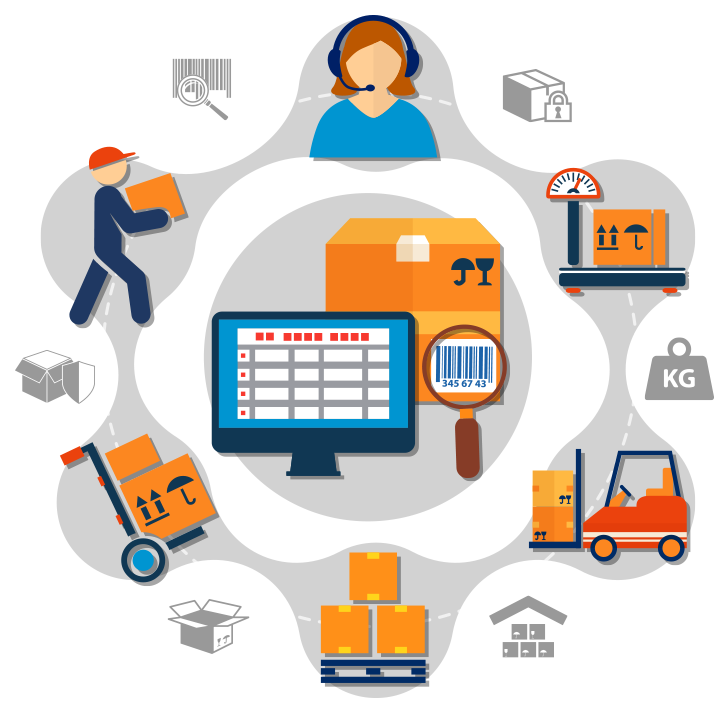

HEALTH OPERATION EFFICIENCY MEASURES

Apply methods of measuring and tracking warehouse performance, from assessing labor performance to measuring production metrics. This helps us to optimize the working process and ensure the efficiency of warehouse management and operation.

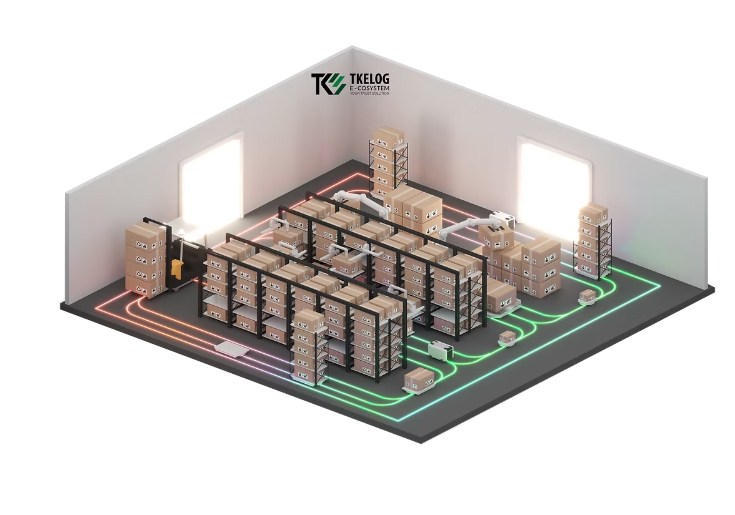

Look MoreEASY SCALE UP SUPPLY CHAIN OPERATIONS

Capable of expanding and expanding supply chain operations to meet growing customer needs. Our flexible system allows us to easily increase our ability to transport, manage and store goods, while minimizing disruption during expansion.

Look MoreSTANDARDIZATION of OPERATION PROCESS

Apply professional warehouse operating standards and procedures to ensure efficiency and consistency in all operations. This helps to optimize processes and reduce errors, while ensuring the efficiency and reliability of logistics services.

Look MoreKEEP OPERATION KNOWLEDGE

Promote the retention and sharing of operational knowledge within the organization. Employees are trained and provided with detailed information on the processes, regulations and skills required to do the job correctly and efficiently.

Look MoreWHY CHOSE US

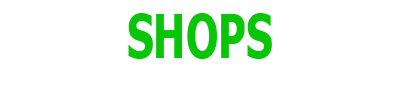

PROFESSIONAL STANDARD WAREHOUSE PROCESS

Receive delivery notice from suppliers or the purchasing department.

Schedule receiving time and allocate resources (manpower, dock, equipment).

Prepare necessary tools (forklifts, checklists, barcode scanners, etc.).

🎯 Ensure readiness of staff and equipment to avoid congestion.

1. Inbound Planning

2. Truck Arrival & Check-in

Driver checks in at the security gate.

Submit relevant documents: delivery note, invoice, shipment code.

Record truck arrival time and license plate in the system.

🎯 Ensure timely and secure tracking of inbound vehicles.

3. Dock Assignment & Truck Docking

Dispatcher assigns an available dock based on cargo type.

Guide truck safely into the designated dock.

Apply wheel chocks and perform safety inspection.

🎯 Ensure safe and efficient unloading setup.

Unload goods into the receiving area.

Verify actual quantity against delivery documents.

Inspect packaging and product condition.

Report any damages, shortages, or excess.

4. Unloading & Inspection

Scan product barcodes to confirm receipt.

Update warehouse management system (WMS/ERP) with item details and quantities.

🎯 Maintain accurate and real-time inventory data.

5. Barcode Scanning & System Update

6. Putaway

System suggests or assigns storage locations.

Transport items to their designated locations.

Scan to confirm storage placement.

🎯 Optimize space and streamline future retrieval.

WAREHOUSE INBOUND PROCESS

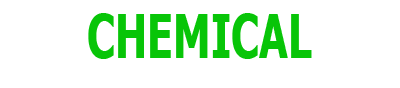

1. Receive Outbound Request

Receive order from sales team, customer, or ERP system.

Check item codes, quantities, and delivery schedule.

🎯 Ensure accurate and timely delivery.

2. Check Inventory & Confirm Availability

Cross-check inventory in WMS.

Verify actual stock locations and quantities.

Notify of any shortages or adjustments.

🎯 Avoid delays or stockouts.

3. Create Picking Plan

Generate picking list by route or zone.

Assign staff and prepare tools (scanners, trolleys…).

🎯 Optimize picking time and movement.

4. Picking Items

Staff pick items from shelves based on the list.

Scan and verify quantity and condition.

Move to packing area.

🎯 Accuracy in item and quantity selection.

5. Packing & Labeling

Double-check before packing.

Attach barcode labels and shipping documents.

Prepare invoices or delivery notes.

🎯 Ensure clear tracking and delivery readiness.

6. Dispatch & System Update

Handover to driver or carrier.

Scan to confirm goods have left the warehouse.

Update inventory and timestamp in system.

WAREHOUSE OUTBOUND PROCESS

HEALTH OPERATION EFFICIENCY MEASURES

STANDARDIZATION OF OPERATION PROCESS

MODULES

KEEP OPERATION KNOWLEDGE

EASY SCALE UP SUPPLY CHAIN OPERATIONS

Our scalable and adaptable system enables seamless expansion of transportation, inventory management, and warehousing capabilities — all while minimizing operational disruptions and maintaining business continuity.

- Easily create new warehouse, Permission management

- Provide document for guide, standard, operation

- Documents dealing with warehouse-specific situations

- Quick employee trainin